Electrophoretic Xim Siv Hauv Ed Txheej Kab

Tshuaj tiv thaiv

Tshuaj npe | CAS Nr. | EC No. |

Linseed yog'i | 57-13-6 : kuv | 200-315-5 |

Phenolic cob | 9003-35-4 | --- |

Suab | 8052-42-4 ib | --- |

Barium sulfate | 7727-43-7 ib | 231-784-4 ib |

Dej | 7732-18-5 ib | 231-791-2 : kuv |

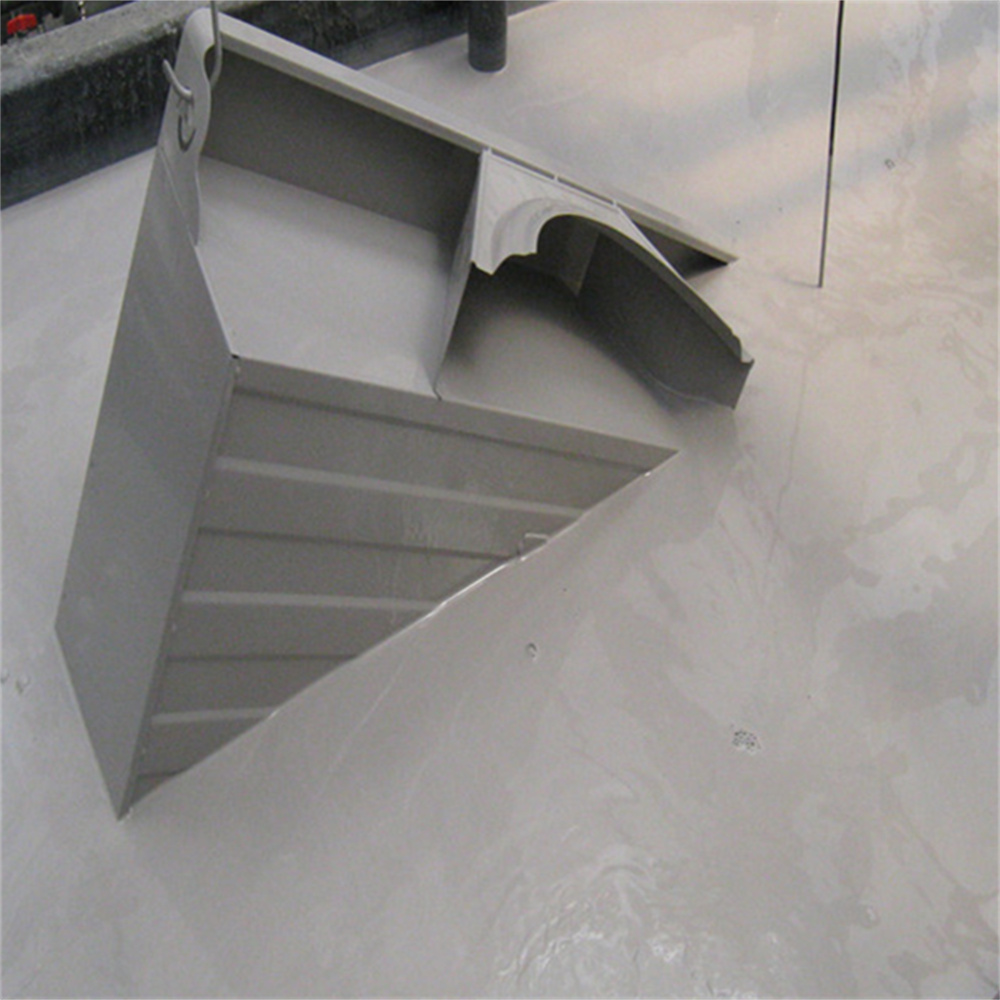

Khoom Qhia

Khoom nta

1. Qib, du thiab zoo nkauj tsos;

2. Zoo da dej tov stability thiab adaptability mus ntev hloov lub voj voog;

3. Muaj zog shrinkage kab noj hniav kuj thiab muaj zog da dej tshuaj tiv thaiv muaj kuab paug;

4. Muaj zog ntug nkaum lub zog thiab corrosion kuj;

5. Zoo zaj duab xis fullness thiab zoo substrate nkaum hwj chim;

6. Haum rau tsheb lub cev, pib qhov chaw, maus taus, hluav taws xob tsheb, tsheb ciav hlau thauj mus los, engineering machinery, khoom siv hauv tsev, kho vajtse, steel pieces thiab lwm yam lag luam.

Qhov txawv

Anode electrophoresis xim, cathodic electrodeposition xim.

Nyob rau hauv lub anode nrog anode electrophoresis xim, acrylic acid, mas siv nyob rau hauv txhuas cov khoom, txhuas oxide xim tiv thaiv tom qab gloss ntawm 50-90 degrees, anode electrophoresis xim thinner, lug siv nyob rau hauv txhuas kev lag luam.

Cathodic electrophoretic xim tuaj yeem muab faib ua: electrophoresis epoxy xim, acrylic xim thiab polyurethane electrophoretic xim.

Epoxy electrophoretic xim: ib qho super ntsev tsuag kev ua tau zoo, ntuav lub zog thiab qhov tob hauv lub substrate phosphate ntsev tsuag kev ua tau zoo txog li 1,000 teev, cov khoom lag luam paub ntau dua rau cov xim dub loj, matte dub, tsaus grey, lub teeb grey raws li. Liab, ntsuab, thiab qee cov xim kuj muaj cov ntawv thov, electrophoresis epoxy xim yog xim xim uas tuaj yeem npog lub substrate, feem ntau yog siv los tiv thaiv corrosion primer, thiab hlau qhov chaw kuj tseem siv tau los ua cov txheej txheem topcoats.

Acrylic thiab polyurethane electrophoretic xim: muaj cov huab cua zoo dua, tsis kam (QUV) yellowing muaj nuj nqi, siab transparency (85-90 degrees) yog tsuas yog siv rau txheej tiv thaiv, ntxiv tshwj xeeb muab tshuaj txhuam yuav deployed, los ntawm qhov kawg ntawm cov nyhuv ntawm txawv xim ci. xim, thiab txhim kho kev ua tau zoo hauv ntsev tsuag kho vajtse ncaj qha electrophoresis.

Xim Paste | |

Qhov tsos: | Dub los yog grey, txawm cia me ntsis stratification, agglomeration tsis pub |

Khoom: | Dub 41 + 2%; Grey 50 + 2% |

Fineness ib (paste): | |

PH tus nqi (25 ℃) | 5.4 + 0.3 |

Conductivity (25 ℃) | 1400 + 300 μs / cm3 |

Emulsion | |

Qhov tsos: | Milky dawb los yog milky yellow kua, cia me ntsis los nag, tab sis yooj yim rau do |

Khoom: | 35 + 2% |

PH tus nqi (25 ℃) | 6.7 + 0.3 |

Conductivity (25 ℃) | 1000 + 300 μs / cm3 |