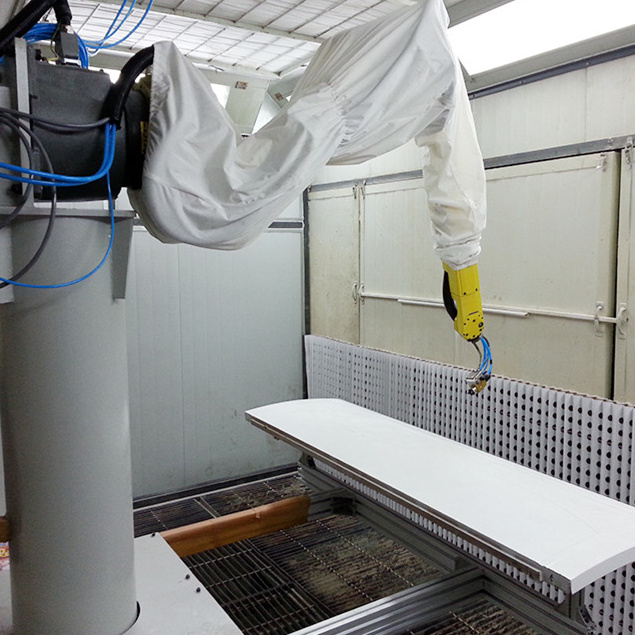

Painting Robot Used In Coating Line

Product Description

Fully automated product handling systems manage the product during all spraying, handling and baking processes.

The system improves the quality of the finished product while increasing production speed and productivity.

The system is easy to install and program, and the robot always delivers the same high quality finish.

Industrial paint robots apply substances without dripping, inconsistency or overspray. Industrial paint robots offer great accessibility to parts. The robot arm is slim and wide, so it can be mounted in multiple locations, such as shelves, walls, roofs or tracks. In addition, it offers greater flexibility and reach. The arms of modern spraying robots have six degrees of freedom.

In general, surfaces that are difficult to reach manually are usually easier to reach by robotic painters. In addition, complex parts with angled or curved surfaces can be painted or coated. The benefits of integrating robotic painting systems in automated production processes include.

The benefits of systems in automated production processes include increased coating throughput, repeatability of the finished product, reduction of workplace injuries, improved reliability, quality and consistency of the coated product, and a greater competitive advantage through quality assurance.

Depending on customer requirements, robotic booths can be equipped with 12 or more color changers. In a system with 12 color changers, it can spray 2K or 3K different hardeners and coatings. It measures the speed of the coating solution. This ensures that the correct mixture of paint and hardener remains consistent. Consistency in paint application helps ensure less overspray. The paint will concentrate more on the product rather than in the air. This also results in a better finish.

Adding a conveyor system and curing oven converts a robotic paint booth into a fully automated turnkey system. The raw material is conveyed into the booth, sprayed, and then conveyed out of the curing oven as a finished product.

Product Display

Benefits of using robot for spraying operation

1. Uniformity of spray coating, stable speed, good gloss, high product qualification rate.

2. Built-in fuel-saving program, high efficiency and save paint, save paint 30%.

3. 24 hours uninterrupted work, high reliability, and improve production capacity.

4. According to workpiece size automatically adjust the gun height, front and back, angle and position, spraying oil volume can be flexibly controlled.

5. Environmental protection, high safety performance, easy to operate and learn.

6. Long service life, no wearing parts, easy maintenance.

7. Programs can be stored in 3000 groups, U disk can be used to copy the program, management is convenient and simple.

8. Wide range of applications, suitable for a variety of shaped workpieces, high utilization rate, dynamic synchronization tracking conveyor belt, with the production line spraying.